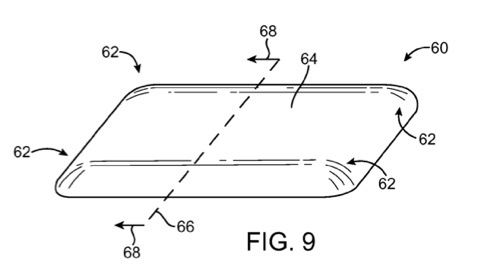

A new patent (number 20100315299) at the US Patent & Trademark Office for fiber-based electronic device structures show that Apple is investigating ways to form structures for electronic devices from fibers.

Per the patent, fibers may be intertwined to form structures for electronic devices and other parts. Fibers may be intertwined using computer-controlled braiding, weaving, and knitting equipment. Binder materials may be selectively incorporated into the intertwined fibers. By controlling the properties of the intertwined fibers and the patterns of incorporated binder, structures can be formed that include antenna windows, sound-transparent and sound-blocking structures, structures that have integral rigid and flexible portions, and tubes with seamless forked portions.

Fiber-based structures such as these may be used to form cables and other parts of headphones or other electronic device accessories, housings for electronic devices such as housings for portable computers, and other structures. The inventors are David Bibi, Matthew Rohrbach and Peter Russell-Clarke.

Here’s Apple’s background and summary of the invention: “Modern weaving, braiding, and knitting equipment can be used to create structures that would be difficult or impossible to implement using other fabrication technologies. For example, woven carbon fiber sheets may be used to form housing structures for electronic devices that are lighter and stronger than housing structures formed from other materials. Flexible cable sheaths may be formed using fiber braiding tools. Many medical devices are formed from fibers. For example, bifurcated vascular grafts and other cardiovascular devices may be formed from fibers.

“Fiber-based structures may be used in forming structures for electronic devices. For example, intertwined fibers may be used in forming housings for electronic devices. The housings may have seamless compound curves. Features such as hooks and pockets may be formed as integral parts of fiber-based structures. These fiber-based structures may, if desired, include structures such as fiber-based cases for carrying an electronic device. Intertwined fibers may also be used to form sheaths for cables, parts of accessories such as headsets, and other structures.

“Fiber intertwining equipment such as tools for weaving, braiding, and knitting may be used to intertwine fibers. The fibers that are intertwined with this equipment may include polymer fibers, metal fibers, insulator-coated metal fibers, glass fibers, or other suitable fibers. Once intertwined, a binder such as epoxy or other suitable matrix may be incorporated into the intertwined structure and cured.

“Parameters that may be varied during the fabrication process include the number of fibers that are incorporated into a particular region of the structure, the spacing between fibers, fiber type, binder type, binder location, etc. By selectively varying these factors, structures can be formed in which different regions of the structures have different flexibilities, different densities (e.g., to adjust audio transparency, moisture penetration, etc.), different conductivities, etc. Shapes that may be formed using the intertwining equipment include forking structures (e.g., bifurcated structures), tubular structures of variable diameter, structures that have potentially complex compound curves, etc.”