A new Apple patent (20110114295) involving heat removal in compact computing systems shows that the company is working ways to make MacBook Pros, MacBooks and MacBook Airs run cooler.

The invention relates generally to small computing devices such as laptop computers and in particular, providing a heat removal system that is efficient in both space and heat removal. A low profile heat removal system suitable for removing excess heat generated by a component operating in a compact computing environment is disclosed. The inventors are Brett W. Degner, Peteris K. Augenbergs, Frank Liang, Amaury J. Herestyn, Dinesh Mathew and Thomas W. Wilson Jr.

Here’s Apple’s background and summary of the invention: “Compact computing devices such as laptop computers, netbook computers, etc. have become ever smaller, lighter and more powerful. One factor contributing to this reduction in size can be attributed to the manufacturer’s ability to fabricate various components of these devices in smaller and smaller sizes, assembling the components in ever more dense configurations, and in most cases increasing the power and or operating speed of such components.

“As processor power and speed has increased, however, so too has the excess heat generated. As the density of the internal components has increased, the ability to efficiently remove the excess heat generated by those operating components having a high heat flux has been become ever more difficult and costly.

“A heat pipe is a heat transfer mechanism that can transport large quantities of heat with a very small difference in temperature between the hotter and colder interfaces and is therefore well suited for use in laptop computers, and other high density, compact computing environments. A typical heat pipe consists of a sealed pipe or tube made of a material with high thermal conductivity such as copper or aluminum. The heat pipe includes a working fluid, (or coolant), chosen to match the operating temperature of the compact computing device. Some example fluids are water, ethanol, acetone, sodium, or mercury. (Clearly, due to the benign nature and excellent thermal characteristics, water is used as the working fluid in consumer products such as laptop computers.)

“Inside the heat pipe’s walls, an optional wick structure exerts a capillary pressure on the liquid phase of the working fluid. The wick structure is typically a sintered metal powder or a series of grooves parallel to the heat pipe axis, but it may be any material capable of exerting capillary pressure on the condensed liquid to wick it back to the heated end. It should be noted, however, that the heat pipe may not need a wick structure if gravity or some other source of acceleration is sufficient to overcome surface tension and cause the condensed liquid to flow back to the heated end.

“Space or volume is at a premium in compact computer environments and it is essential that any heat removal system must be able to maximize heat transfer while minimizing the space occupied. In addition to minimizing the space required, it is desirable that the heat removal system be relatively inexpensive to fabricate. The cost of fabrication is relatively high when the heat removal system is fabricated from especially dedicated and unique components as distinguished from being fabricated from stock materials.

“Although the prior art effectively dissipates heat from electronic devices, there is a continuing need for alternative designs that do not substantially add additional height to the existing Z stack height, that effectively dissipate heat and are relatively inexpensive to fabricate.

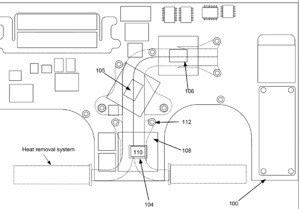

“The invention relates to systems, methods, and apparatus for efficiently removing heat from components in a compact computing system such as a laptop or netbook computer. In one embodiment, a compact computer heat removal system used for removing heat generated by an integrated circuit is described. In the described embodiment, the integrated circuit is mounted to a substrate that in turn is mounted to a motherboard.

“The heat removal system includes at least a heat pipe in thermal contact with the integrated circuit, the heat pipe is arranged to carry a heat exchanging medium that is used to transfer heat generated by the integrated circuit to an external heat sink in thermal contact with the heat pipe. The heat removal system also includes a reduced thickness integrated beam spring structure having a substantially uniform thickness used to mechanically couple the heat pipe to the motherboard. The reduced thickness of the beam structure commensurably reduces the height of the heat removal system that in turn reduces the overall integrated circuit stack height.

“A compact computer heat removal system used for removing heat generated by an integrated circuit where the integrated circuit is mounted to a substrate that, in turn, is mounted to a motherboard. The compact computer heat removal system includes at least a slug in direct contact with a surface of the integrated surface. A heat pipe in thermal contact with the integrated circuit by way of the slug is used to provide support for the heat pipe and to provide a thermal conduction path between the integrated circuit and the heat pipe.

“In the described embodiment, the heat pipe carries a heat exchanging medium used to transfer heat generated by the integrated circuit to an external heat sink in thermal contact with the heat pipe. The compact computer heat removal system also includes a windowed stage having an opening arranged to accommodate the slug. The windowed stage is mechanically connected to the motherboard by way of fasteners. By accommodating the slug within the opening, the windowed stage reduces the thickness of the heat removal system that commensurably reduces an overall integrated circuit stack height.

“In yet another embodiment, a heat removal system suitably configured to transfer heat generated by an operating component in a compact computer to the external environment is described. The heat removal system includes at least a heat pipe positioned in direct thermal contact with the operational component, at least one lateral winglet integrally formed with and of substantially the same material as the heat pipe, an upper surface of the winglet being substantially flush with a lower surface of the heat pipe such that substantially all of the at least one winglet extends below the lower surface of the heat pipe, the upper surface extending laterally out from the heat pipe to form a supporting surface, and a stage portion having a first end, the first end having a lower surface supported by the supporting surface such that an upper surface of the stage portion is substantially flush with an upper surface of the heat pipe.

“In still another embodiment, a method for removing heat generated by an integrated circuit is described where the integrated circuit is mounted to a substrate, the substrate mounted to a motherboard. The method can be carried out by performing at least the following operations: providing a heat pipe in thermal contact with the integrated circuit, the heat pipe arranged to carry a heat exchanging medium that is used to transfer heat received from the integrated circuit to a heat sink, and using a reduced thickness integrated beam spring structure to mechanically couple the heat pipe to the motherboard. In the described embodiment, the reduced thickness of the beam structure reduces an overall integrated circuit stack height.

“A method for removing heat generated by an integrated circuit is described. In the described embodiment, the integrated circuit is mounted to a substrate that in turn is mounted to a motherboard. The method can be carried out by performing at least the following operations. Providing a slug in direct contact with a surface of the integrated surface, providing a heat pipe in thermal contact with the integrated circuit by way of the slug, the slug being used to provide support for the heat pipe and to provide a thermal conduction path between the integrated circuit and the heat pipe, providing a windowed stage having an opening arranged to accommodate the slug, the windowed stage being mechanically connected to the motherboard by way of fasteners. The heat removal system thickness is commensurably reduced by the windowed stage accommodating the slug within the opening.”

— Dennis Sellers