A new Apple patent (number 20120028480) has appeared at the U.S. Patent and Trademark Office. Among other things it would facilitate the assembly of Apple devices via programmable magnetic devices.

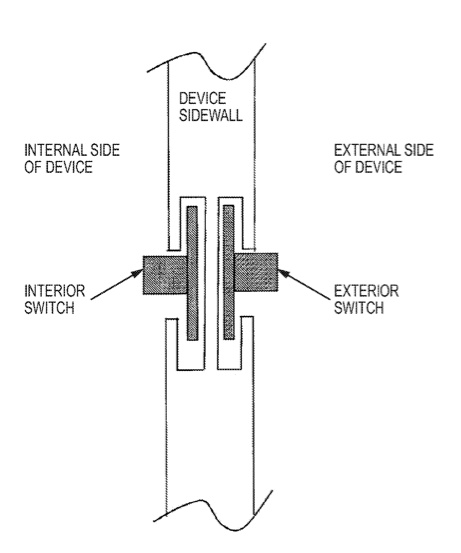

The patent involves alignment and connection for devices. relate generally to programmable magnetic devices, and more particularly to multi-part devices that may be joined or separated through programmable magnets. A plug or connector including a coded magnet and an electrical contact is disclosed.

As the plug approaches a corresponding port, the coded magnet interacts with a magnet within the port. The interaction between the plug coded magnet and the port coded magnet provides a force to connect and/or align the plug with the port. Once the plug is received within the port, if a process is completed, the coded magnets polarities are altered to eject the plug from the port.

“Correlated magnets” or “coded magnets” are magnetic structures formed of multiple individual magnetic elements, each of which has both a north and a south pole. The individual magnetic elements may vary in terms of which pole faces a surface of a coded magnet. So a single coded magnet 10 may have multiple magnetic poles on a single surface, and these multiple magnetic poles may cooperate to form a pattern of north and south poles.

A variety of different input devices may be enhanced through the use of coded magnetic surfaces, according to Apple. For example, individual keys of a keyboard may be backed with a coded magnetic structure. Likewise, the surface of the keyboard below each key may have a coded magnetic structure formed thereon that, in conjunction with the coded magnet of the keycap. In alternative embodiments, only one of the keycap and keyboard may utilize a coded magnet while the other is a planar magnet or ferrous material.

Apple says it should be appreciated that the precise alignment and “homing” that may be achieved with appropriately configured pairs of correlated magnetic surfaces may provide useful functionality for precision assembly of devices. As one example, a laptop computer generally has precise tolerances and positions for all its constituent elements within the laptop chassis. If one element is misplaced, the laptop may not function properly or may not pass a final assembly inspection.

Continuing this example, each element to be placed within a laptop computer may have a coded magnetic surface with a unique magnetic code. A certain position within the laptop chassis may have the complementary or attracting coded magnetic surface. Thus, when the element is near that position, it may self-align at the position. Further, such alignment is not necessarily limited to lateral motion but may include rotational alignment as well. This precision alignment may facilitate construction or assembly of fault-intolerant devices.

The inventors are Brett Bilbrey, Aleskander Pance, Peter Arnold, David I. Simon, Jean Lee, Michael D. Hillman, Gregory L. Tice, Vijay Iyer and Bradley Spare.