A new Apple patent (number 20110189004) shows that the company is working on ways to improve air flow in upcoming Macs.

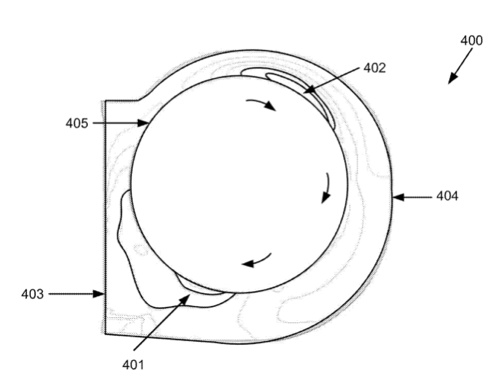

The patent involves a fan inlet and method. method and apparatus to improve air flow in an air circulating fan assembly by forming an inlet opening in a fan assembly is disclosed. A static air pressure profile is calculated along a top portion of the fan assembly configured to operate in an enclosure.

The shape of a section of the inlet opening in the top portion of the fan assembly is changed based on a pressure contour of the calculated static air pressure profile. The method is repeated iteratively one or more times using an inlet opening changed by a previously calculated static air pressure profile when calculating a subsequent static air pressure profile.

The inlet opening is positioned in the top surface of the fan assembly so that the centroid of the inlet opening is laterally offset with respect to the rotational axis of an impeller in the fan assembly. The inventors are Jesse T. Dybenko, Frank Liang, Amaury J. Heresztyn, Brett W. Degner, Thomas W. Wilson Jr., Peteris K.Augenbergs and Connor R. Duke.

Here’s Apple’s background and summary of the invention: “The performance of computational components and storage devices in computing systems, such as personal computers and rack mounted servers, require effective cooling mechanisms to ensure that the components and devices used inside operate in a preferred temperature range. The operational stability of central processing units (CPUs), video processing units, memory and storage devices, for example, can be adversely affected by heat accumulation within enclosed spaces in which they are housed, such as encountered in relatively thin notebook computers.

“With each newly introduced computing system, the performance of components used internally are being increased, while simultaneously, the dimensions of the external enclosure that houses the computing system are being decreased, thereby challenging the computer system designers to devise more efficient cooling methods. The narrow height dimensions of portable computer housings can require more efficient cooling methods than can be provided by thermal conduction alone or even when combined with conventional air circulation fan designs.

“Air circulation fans within computing systems can include axial fans that move air parallel to the rotational axis of the fan’s impeller and centrifugal fans that blow air through an outlet perpendicular to an air inlet opening. Several geometric properties of a centrifugal fan’s shape can affect its air flow performance, including the size, shape and orientation of the air inlet opening through which air is drawn when rotating the fan’s impeller.

“In a typical prior art centrifugal fan, a circular inlet opening in the fan’s housing is positioned concentric with the rotational axis of an impeller situated inside the fan housing. Increasing the diameter of the circular inlet opening beyond a certain size can decrease air flow (rather than increase it as intended) due to air being expelled upward from the rotating impeller blades and thereby forcing some air out of the inlet opening rather than drawing air in. Prior art methods have designed variously shaped inlet openings for centrifugal fans to change the fan’s air flow. Such ad hoc methods can change the air flow but not necessarily maximize the flow rate through the fan in its intended application.

“None of the prior art methods known to the applicants have systematically designed the inlet opening according to calculated pressure contour profiles on the fan housing’s surface operating in situ. Thus there exists a need for an improved method to form an inlet opening in a cooling fan to maximize flow rate.

“This paper describes various embodiments that relate to methods and apparatus to improve air flow and increase flow rate in an air circulating fan assembly. In described embodiments, a method for forming an inlet opening in a fan assembly’s housing is described. The method comprises calculating a static air pressure profile along a top portion of the fan housing configured to operate in an enclosure and changing the shape of a section of the inlet opening in the top portion of the fan housing based on a pressure contour of the calculated air pressure profile.

“The fan assembly includes an impeller mounted on a bottom portion of the fan housing, a housing sidewall perpendicular to the bottom portion and enclosing the fan assembly to form an outlet opening along one side, and the top portion of the fan housing having an inlet opening perpendicular to the outlet opening and positioned over the impeller. In some embodiments, the method can be repeated iteratively one or more times using an inlet opening changed by a previously calculated static air pressure profile when calculating a subsequent static air pressure profile. In some embodiments, the fan assembly is a centrifugal fan.

“In an embodiment, the centroid of the changed inlet opening is displaced laterally from a rotational axis of the impeller in the air circulating fan assembly. The changed inlet opening can be a non-circular, smoothly convex geometric curve with no discontinuities or corner bends. In some embodiments the interior surface of the fan assembly’s housing sidewall can follow a smoothly convex geometric curve, also with no discontinuities or corner bends.

“In another embodiment, an air circulating fan assembly is described. The air circulating fan assembly comprises an impeller mounted on a bottom portion of a housing of the fan assembly, a housing sidewall perpendicular to the bottom portion and enclosing the fan assembly to form an outlet opening along one side, and a top portion of the fan housing having an inlet opening perpendicular to the outlet opening and positioned over the impeller.

“The shape of a section of the inlet opening in the top portion of the fan housing is based on a pressure contour of a calculated static air pressure profile along the top portion of the fan housing when configured to operate in an enclosure. In an embodiment, the shape of the inlet opening in the fan housing is determined by using a previously determined inlet opening when calculating a subsequent static air pressure profile along the top portion of the fan housing. Preferably the fan assembly is a centrifugal fan.

“In a further embodiment, the centroid of an inlet opening in the top portion of a fan housing is displaced laterally from a rotational axis of the impeller. The shape of the inlet opening can be a non-circular, smoothly convex, arc-shaped geometric curve with no discontinuities or corner bends. In some embodiments the interior surface of the fan assembly’s housing sidewall can follow a smoothly convex geometric curve, also with no discontinuities or corner bends.”

Another Apple patent (number 20110188178) also appeared today and is for a high tolerance connection between elements. This is directed to connecting two or more elements using an intermediate element constructed from a material that changes between states.

An electronic device can include one or more components constructed by connecting several elements. To provide a connection having a reduced or small size or cross-section and construct a component having high tolerances, a material can be provided in a first state in which it flows between the elements before changing to a second state in which it adheres to the elements and provides a structurally sound connection.

For example, a plastic can be molded between the elements. As another example, a composite material can be brazed between the elements. In some cases, internal surfaces of the elements can include one or more features for enhancing a bond between the elements and the material providing the interface between the elements. The inventors are Scott Meyers, Mattia Pascolini, Richard Dinh, Trent Weber, Robert Schlub, Josh Nickel, Robert Hill, Nanbo Jin and Tang Tan.

— Dennis Sellers