An Apple patent (number 20110056836) for anodization and polish surface treatment — used its the company’s iOS line of products — has appeared at the US Patent & Trademark Office.

Per the patent, a metal surface treated to have a distinct cosmetic appearance such as an integral layer that is glossy may be used in electronic devices. The surface treatment may include polishing a metal surface, texturing the polished metal surface, polishing the textured surface, followed by anodizing the surface, and then polishing the anodized surface. The metal surface may also be dyed to impart a rich color to the surface. The inventors are Masahige Tatebe, Howard Bujtor, Jody Akana and Jonathan P. Ive.

Here’s Apple’s background and summary of the invention: “Many products in the commercial and consumer industries are metal articles, or contain metal parts. The metal surfaces of these products may be treated by any number of processes to alter the surface to create a desired effect, either functional, cosmetic, or both. One example of such a surface treatment is anodization.

“Anodizing a metal surface converts a portion of the metal surface into a metal oxide, thereby creating a metal oxide layer. Anodized metal surfaces provide increased corrosion resistance and wear resistance. Anodized metal surfaces may also be used in obtaining a cosmetic effect, such as utilizing the porous nature of the metal oxide layer created by anodization for absorbing dyes to impart a color to the anodized metal surface.

‘The cosmetic effect of surface treatments to products that are metal articles, or have metal parts, can be of great importance. In consumer product industries, such as the electronics industry, visual aesthetics may be a deciding factor in a consumer’s decision to purchase one product over another. Accordingly, there is a continuing need for new surface treatments, or combinations of surface treatments, for metal surfaces to create products with new and different visual appearances or cosmetic effects.

“A series of surface treatments may be performed on a surface of a metal part or article to create an integral layer having a desired cosmetic effect. The integral layer resembles a coating or layer that has been applied to the metal surface, but is actually an integral or intrinsic part of the metal article that has been treated to obtain the desired cosmetic effect. In other words, the integral or intrinsic layer is not a separate coating or film and the desired cosmetic effect is therefore achieved without the application of a separate coating or film, such as a lacquer or paint. The integral layer may be a coatingless layer that also has a sparkling effect, a rich color, and/or a glossy or shiny appearance. The integral layer may also provide additional characteristics such as corrosion and wear resistance. The integral layer may be applied to a broad range of metal articles including household appliances and cookware, automotive parts, athletic equipment, and electronic components.

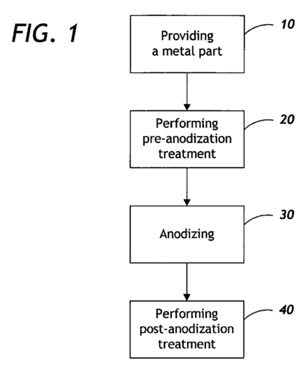

“In one embodiment, a method may include providing a metal part having a surface, polishing the surface, anodizing the surface to create an oxide layer after the step of polishing the surface, and polishing the oxide layer after the step of anodizing. The method may provide the metal part with an integral surface that is glossy.

“In another embodiment, a method for treating a metal surface of a metal part to obtain an integral surface that is glossy is disclosed. The method may include providing a rough metal surface, forming a smooth surface from the rough metal surface, forming a surface with a plurality of peaks from the smooth surface, rounding the plurality of peaks, forming a metal oxide layer having a plurality of rounded peaks, imparting a color to the metal oxide layer, and forming a smooth surface from the colored metal oxide layer.

“In yet another embodiment, a method for treating a surface of a metal part to obtain an integral surface that is glossy and sparkling is disclosed. The method may include providing the metal part, texturing the metal part to provide a surface with a plurality of peaks, polishing the textured metal part to round the plurality of peaks, anodizing the polished metal part, and polishing the anodized metal part.”

— Dennis Sellers